Manufacturing

Needs for Shapes, Functions, Quantity, Delivery Time, Cost. Our Production Facilities,

Technologies and Production Management of The Highest Standard Meet All Needs,

Giving Top Priority to Quality.

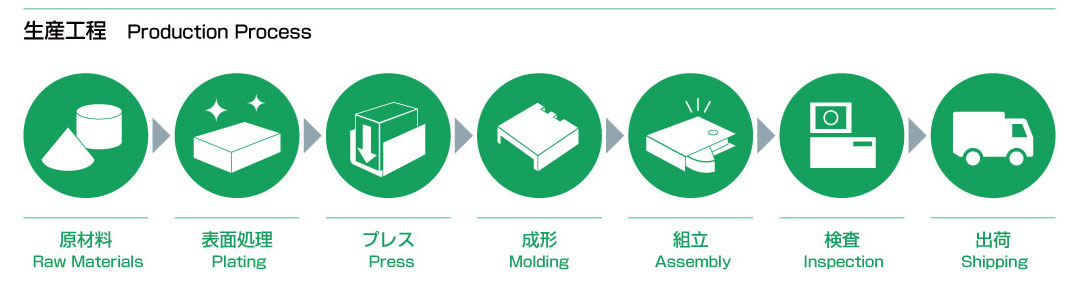

Our original production technology “MIK Original” has been demonstrated according to its special characteristics at each production site of the Head Office, Iwaki Factory, Matsuyama Factory, and the Thai Factory, and has achieved integrated production from plating and press processing to resin molding and assembly. In particular, the “MIK Original” production system based on patents, including the “Swingner System”, which makes parts on a pallet into products, while giving vibration at once, the “Hoop Injection Machine”, which continuously molds hoop material at high-speed, and the “Original Vertical Injection Machine”, which achieves more than 1.5 times the production capability of conventional machines, offers great advantages over other companies, with enhanced quality, delivery time, and cost performance. Also, not only the patented technology, but also the “skilled techniques” and cooperative working of our engineers and operators has firmly established Mik Electronic’s advanced production technology.

-

Swingner System

With this system, we can put parts into the holes on each pallet by vibrating it and finish setting up the parts all at once. -

Auto Swingner System

Structure automating assembly of the Swingner System. -

Hoop Injection Machine

Hoops are consecutively formed at high speeds by pouring hoop materials into a horizontal molding machine. Its production capacity has been enhanced to more than double that of existing machines by our “MIK Original” processing technologies. -

Original Vertical Injection Machine

Normally, molds with 2 lower surfaces and 1 upper surface are used, but by making the lower surfaces to be 3 lower surfaces, the capability becomes 1.5 times more than that of a conventional injection machine.